-

Team TechTree

09:09 06th Mar, 2020

From Foldable Phones to Bendable Concrete | TechTree.com

From Foldable Phones to Bendable Concrete

The world is fast moving towards accepting the cliché that flexibility is the key to longevity, be it on phones or in building blocks

Just about when one was coming to grips with the fact that foldable phones are here to stay, there are reports that scientists have now developed a brand of bendable concrete. Opinion is divided on the durability of the smartphones that bend the glass but in the case of the concrete, the consensus is that they would support strength and durability.

Researchers at the Swinburne University of Technology in Melbourne say the process that allows them to bend concrete could go mainstream soon enough and once it does, could lower the carbon footprint that one associates with making construction material. What’s more, the bendable concrete could be a boon for builders in earthquake zones.

The new concrete takes a leaf out of stories about engineers in ancient Rome who mixed volcanic ash and quicklime to create building material. The scientists point out that this could be one of the reasons why some of these structures continue to stand to this day.

So, the scientists at Melbourne used fly ash, a by-product of power generation through coal-based plants, to create their brand of bendable concrete. They managed to incorporate synthetic fibres into the concrete mix which removes the need to heat the concrete mix and then cure it to create the slabs.

According to the Constructor.org, bendable concrete exhibits the property of ductile material unlike the brittle nature of conventional concrete. It says that besides higher durability and strength, this form of concrete offers higher ductility and resistance to cracking with self-healing properties.

In their note, the scientists say that this material incorporates industrial waste products such as fly ash – a by-product of coal-fired power stations. It is especially suited for construction in earthquake zones where the brittle nature of conventional concrete often leads to disastrous building collapses.

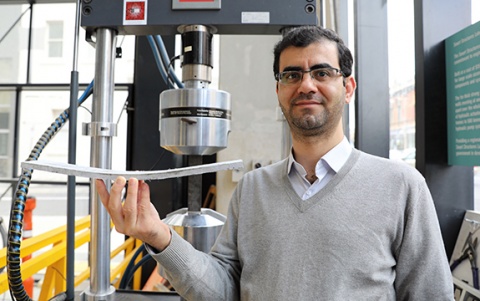

Swinburne researchers Dr Behzad Nematollahi and Professor Jay Sanjayan say that while traditional concrete is not only prone to shatter when being stretched or bent, but also has a huge carbon footprint due to calcination of limestone to produce its key ingredient, cement. By using industrial waste products we have done away with the need for concrete, making the product more sustainable, they say.

“Production of this novel concrete requires about 36 per cent less energy and emits up to 76 per cent less carbon dioxide as compared to conventional bendable concrete made of cement,” says Dr Nematollahi.

Bendable concrete isn't a new concept. It was first developed by Dr. Victor Li, a civil and environmental engineering professor at the University of Michigan, in the early 1990s. However, the issue has always been producing material affordably.

TAGS: bendable concrete, concrete, Design, construction, Swinburne University

- DRIFE Begins Operations in Namma Bengaluru

- Sevenaire launches ‘NEPTUNE’ – 24W Portable Speaker with RGB LED Lights

- Inbase launches ‘Urban Q1 Pro’ TWS Earbuds with Smart Touch control in India

- Airtel announces Rs 6000 cashback on purchase of smartphones from leading brands

- 78% of Indians are saving to spend during the festive season and 72% will splurge on gadgets & electronics

- 5 Tips For Buying A TV This Festive Season

- Facebook launches its largest creator education program in India

- 5 educational tech toys for young and aspiring engineers

- Mid-range smartphones emerge as customer favourites this festive season, reveals Amazon survey

- COLORFUL Launches Onebot M24A1 AIO PC for Professionals

TECHTREE